Heath,

I am curious why the three belt system was used. Very nice restore, looks like just came off the showroom floor. What hp motor did you use? That baby has a lot of years left in it thats for sure.

MIke

I am curious why the three belt system was used. Very nice restore, looks like just came off the showroom floor. What hp motor did you use? That baby has a lot of years left in it thats for sure.

MIke

Hey folks,

As made evident by a few of my posts regarding some of my other tool rebuilds, I have a thing for "vintage" tools, and am slowly but surely setting up shop with stationary tools exclusively from the golden age of cast iron.

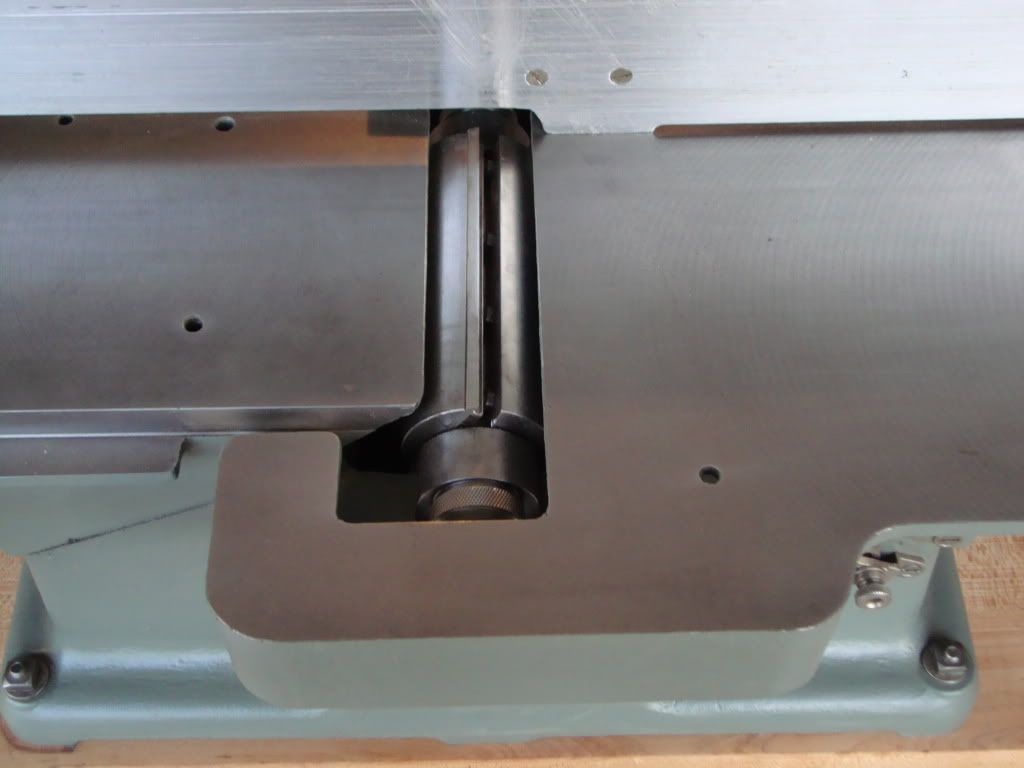

I spent the better part of last weekend finishing the reassembly, setting the knives, (thanks Bob Vaugn!), and otherwise putting the final touches on the jointer project I've been working on. Space is tight on my side of the garage, and I think this little guy, (6" cutterhead, 38" infeed/outfeed) is the perfect balance of capacity & footprint until my wife finally caves & moves out of the garage....

I put it through the paces this weekend, and it works like a champ - perfect 4 square!:icon_cheers

As she came home:

& here she is now:

Thanks for letting me share!