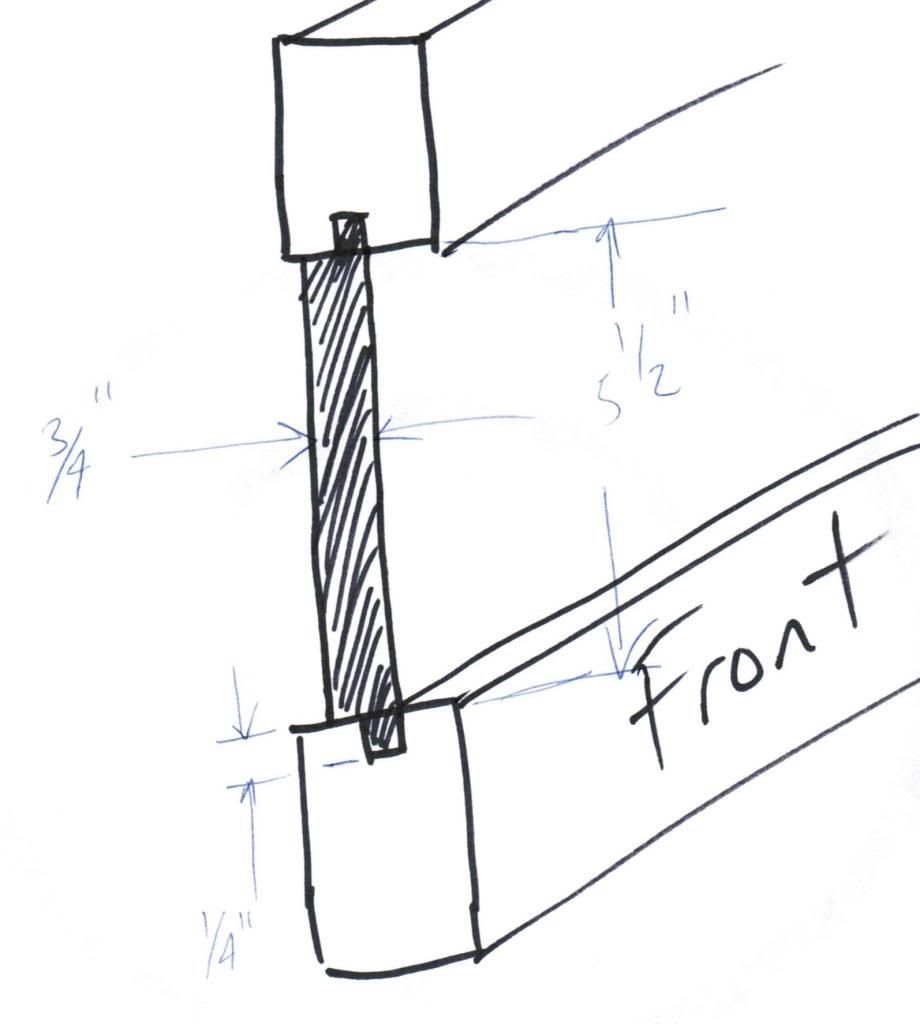

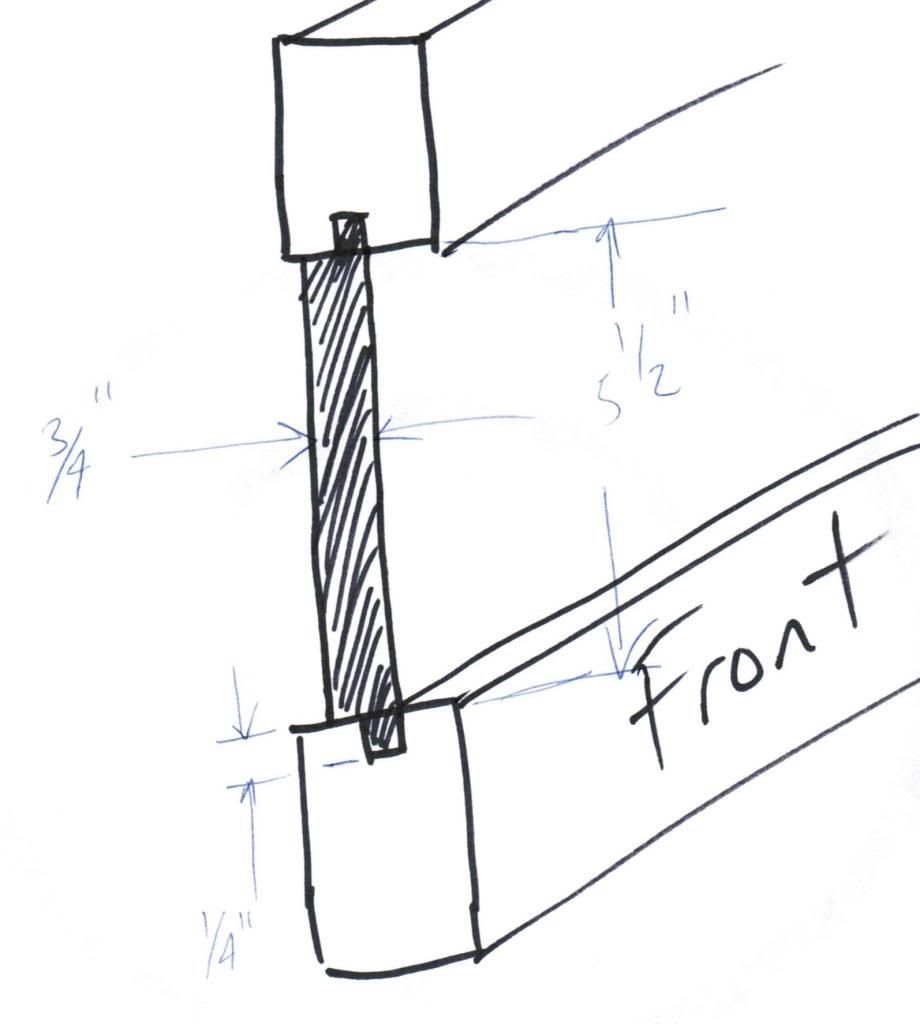

I am working on the side rails for my walnut bed and would like some advice on the best way to glue up this part of the project. I have attached a very crude sketch of the side rail to show my plan (based on the fact that I already have two very nice 6" wide boards planed down to 3/4" thickness). Main questions is: will a rabbet that is only 1/4" deep be sufficient in this application? how wide should it be ideally?

Thanks for the advice.

Thanks for the advice.