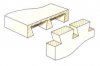

Last night Leigh told me she wanted me to build her a shelf but she wants it open. (I wish I could understand woman sometimes) After she got fetup with me she told me it is like a book shelf but open. She told me today that it will not be hung on the wall, but instead it will sit on the floor infront of a window. HD has poplar 1x8x36 for $8 a board. I figure for about $50. Here is a sketchup drawing.

This might be a good time to get that kreg pocket hole kit. he he:-D

Not sure if I want to dato for the shelves or dovetail. I dont have a dovetail jig. Can I make my own dovetail jig? If so, how? What would be a complementing stain to use?

This might be a good time to get that kreg pocket hole kit. he he:-D

Not sure if I want to dato for the shelves or dovetail. I dont have a dovetail jig. Can I make my own dovetail jig? If so, how? What would be a complementing stain to use?