I received a K40 laser over Christmas and have worked with it a few times. I knew going in I would be rebuilding it. I very rarely can leave stuff like this alone. There are several different projects out there about reworking the K40 using the existing enclosure and expanding it out to a 12x24 work area after deliberating I decided I wanted to go the full rebuild route. the only think I will be keeping from the K40 are the PSU and Tube and possibly the controller its a Laser Burn compatible board but it has none of the things I'm used to from my 3d printers. I've started the rebuild and about have the frame completed. Being the highly skilled individual I am I decided also it would be a good time to start finishing my basement. I'm still not entirely sure where my brain was for that decision. Anyway... Here are a few pics of the build from the time I got the printer to starting to collect parts to today.

The K40 out of the box and keeping my 3D Printers Company.

First Round of extrusions. Roughly 15000 linear millimeters, about 50ft, I ended up picking up another 10000mm and have used all but about 3000mm of that. Only had 1 or 10 bad cuts, fortunately for the most part I was able to salvage my creative cuts into other parts.

Working on my 3D Model in Fusion 360 to give me a general idea of what I was doing.

Initial frame up, My basement exploded in the background with my genius idea of starting two projects at once.

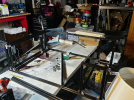

checking that my bed would handle a job that I am going to do for my neighbor next year. I couldn't do it this year for him since my work area was so small. This is a 12x24 work area and should handle 90% or more of anything I'd ever want to do, anything bigger I'll just farm out to one of the many services out there now.

I have the lid roughed in.

It works as well. I have a couple of 40N gas shocks on order for the lid so it will not slam down on me.

The exterior will be covered with 3mm Black Plexi and the internal walls will have the same treatment, that way if I ever have a rogue laser its got to get through 6mm of surface, which hopefully with the way the beam would spread would prevent any free range laser beams. That and the fact that I watch it like a hawk when engraving or cutting. Its one thing to trust my 3D printers and their thermal shut off after 100's of hours of printing, but with that not being an option and the greater potential of danger with the laser I'm never more than about 15ft from it.

I still have some work to do sorting out the frame a little more and planning where to mount a few things. I'm waiting on my first set of linear rails to come in so i can start working on building out the Y-Axis and am going to have an adjustable bed as well and have to scrounge up my parts for that.

It's been a fun project so far and looking forward to getting it fully functional.

The K40 out of the box and keeping my 3D Printers Company.

First Round of extrusions. Roughly 15000 linear millimeters, about 50ft, I ended up picking up another 10000mm and have used all but about 3000mm of that. Only had 1 or 10 bad cuts, fortunately for the most part I was able to salvage my creative cuts into other parts.

Working on my 3D Model in Fusion 360 to give me a general idea of what I was doing.

Initial frame up, My basement exploded in the background with my genius idea of starting two projects at once.

checking that my bed would handle a job that I am going to do for my neighbor next year. I couldn't do it this year for him since my work area was so small. This is a 12x24 work area and should handle 90% or more of anything I'd ever want to do, anything bigger I'll just farm out to one of the many services out there now.

I have the lid roughed in.

It works as well. I have a couple of 40N gas shocks on order for the lid so it will not slam down on me.

The exterior will be covered with 3mm Black Plexi and the internal walls will have the same treatment, that way if I ever have a rogue laser its got to get through 6mm of surface, which hopefully with the way the beam would spread would prevent any free range laser beams. That and the fact that I watch it like a hawk when engraving or cutting. Its one thing to trust my 3D printers and their thermal shut off after 100's of hours of printing, but with that not being an option and the greater potential of danger with the laser I'm never more than about 15ft from it.

I still have some work to do sorting out the frame a little more and planning where to mount a few things. I'm waiting on my first set of linear rails to come in so i can start working on building out the Y-Axis and am going to have an adjustable bed as well and have to scrounge up my parts for that.

It's been a fun project so far and looking forward to getting it fully functional.