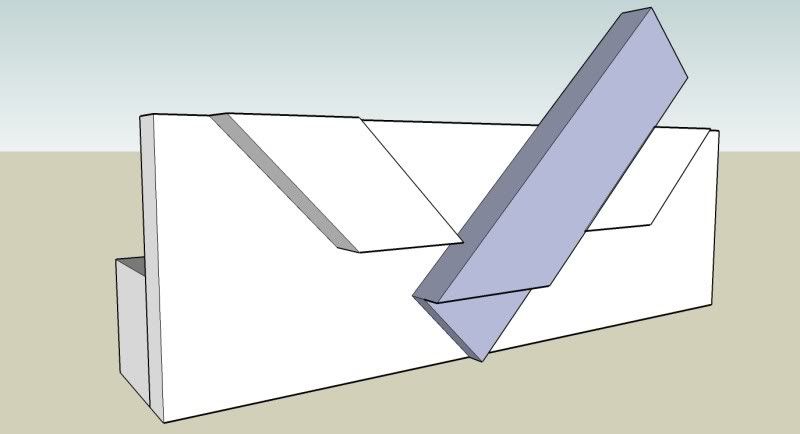

Does anyone have any hints on achieving the perfect half mitered lap joint? I have used two versions from Woodsmith and come along fine until the mitered cuts are made to join the pieces together. They are lined up looking from the rear of the tablesaw even with the corner, looks simple but I can't get a perfect cut each time. I am using a block with hopes of each cut being the same, occasionally one or two will cut too far up into the shoulder distroying my perfect cut. Comments welcomed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Half mitered lap joing

- Thread starter lwhughes149

- Start date

- Status

- Not open for further replies.

If memory serves me correct, and it may not, I remember these as having one member square, with a miter on the face. The other is a miter, with the back removed. If this what you are trying to do, I would use a router with a pattern bit to remove the waste. Cut a 45 on a piece of stock, and clamp it to square end member. Using 45 as a guide for bearing, hog out the waste. Use a square end board to guide router bit and hog out back of mitered piece. Clear as mud? Bruce

Are you using a router or a TS with dado?. I have had problems with work rocking up on both, so I usually place a feather board on the fence to keep the work flat to the table. If you are using a plunge router to remove the waste, I can't help much except to say I have best luck taking thin cuts and making multiple passes.

This is just technique info, as I have not made any half-lapped miter joints yet, so take it for what it may be worth to you.

Go

This is just technique info, as I have not made any half-lapped miter joints yet, so take it for what it may be worth to you.

Go

The technique that I am using this second time, comes from Woodsmith, I will give the book number tomorrow am, it calls for a jig, which I made and used, that part of the process worked great, the jig puts the angles in place, the problems comes when the last cuts are made. Will give book number for those who have woodsmith. It clearly shows the problem I have had on both applications.

This is a joint that must be mastered, it is a good joint with lots of glue strength, can be used in so many applications in the woodworking of furniture to say nothing of picture frames. Woodsmith has a demo that shows how to make and use the jig that I made for my second attempt. It looks so simple that when I made one of the cuts into the shoulder I was supprised, I just knew I would be able to make my perfect each and everytime. Not so. I will not give up.:BangHead:

If memory serves me correctly the book number is 167

This is a joint that must be mastered, it is a good joint with lots of glue strength, can be used in so many applications in the woodworking of furniture to say nothing of picture frames. Woodsmith has a demo that shows how to make and use the jig that I made for my second attempt. It looks so simple that when I made one of the cuts into the shoulder I was supprised, I just knew I would be able to make my perfect each and everytime. Not so. I will not give up.:BangHead:

If memory serves me correctly the book number is 167

Don't know if you have seen this, but this is a video from woodsmith, in reference to the article in issue 167.

http://www.woodsmith.com/issues/167/videos/mitered-half-lap-joints/

http://www.woodsmith.com/issues/167/videos/mitered-half-lap-joints/

M

McRabbet

The jig that Threejs (David) suggests is a good one as long as the stock is flat on both sides and equal thickness. I have used a dado blade on my table saw to cut half laps with a miter gauge, but it is very important to keep the stock tight to the table when making the cuts. All of the stock must be milled exactly to the same thickness as well. If you want to make this joint using decorative framing stock, then the top cut (through the uneven decorative side) can be done on a radial arm saw equipped with a dado blade. I would place stock-holding fences on the RAS table (like David's jig above, but secured to the table) to insure the accuracy of the 45 degree miter angle.

David & Rob, I you will look at the video, come to the last cuts where you have removed the jig and are making the last cuts at 45 degree angles, stop set on each cut to keep the cuts the same, you are seeing the cut from the backside of the tablesaw and coming to the fence side of the point, that is the place where I am having trouble, some come out great with a perfect miter on the final piece but some will cut too deep into the shoulder. I am used two woodsmith examples and had the same results each time. I think it is just difficult to see the line up with the saw blade from the rear of the tablesaw, I have a outfeed table behind my tablesaw.

- Status

- Not open for further replies.