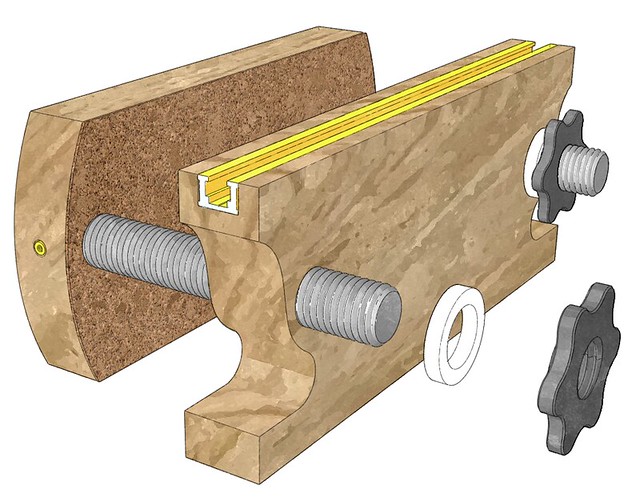

This thread's vise had a couple of minor shortcomings (IMO, anyway) and I just finished this upgraded version. My goal was a superb vise for hand dovetailing in the way that I like to work. YMMV

Some changes were larger clamping lugs, "crubber" on chop only, thicker stock, and a T-track.

With the previous vise using clamps to hold the tail board for marking the pin board, I felt like I needed three hands. After much thought and discarded ideas, I decided on a T-track and Kreg track clamps to hold the tail board like this:

The left clamp holds a Veritas saddle square which provides two surfaces to register the boards' top (or bottom) edges. First, insert the tail board so it overhangs the chop and temporarily clamp it with the right clamp. Insert the pin board from the bottom against the saddle square and the tail board and clamp it with the chop. Finally, align the tail board with the pin board, clamp, and you are ready to mark. This is a lot of words for steps that take well less than a minute!

Some changes were larger clamping lugs, "crubber" on chop only, thicker stock, and a T-track.

With the previous vise using clamps to hold the tail board for marking the pin board, I felt like I needed three hands. After much thought and discarded ideas, I decided on a T-track and Kreg track clamps to hold the tail board like this:

The left clamp holds a Veritas saddle square which provides two surfaces to register the boards' top (or bottom) edges. First, insert the tail board so it overhangs the chop and temporarily clamp it with the right clamp. Insert the pin board from the bottom against the saddle square and the tail board and clamp it with the chop. Finally, align the tail board with the pin board, clamp, and you are ready to mark. This is a lot of words for steps that take well less than a minute!

Last edited: