I have an old PowerMatic planer, circa 1964, whose knives are being re-sharpened and in the meantime I am inspecting the drive belts. I found one that is very worn and cracked so I removed it and measured its length by wrapping a flexible tape around the outside and got a length of 63.5 +- 0.125" based on several measurements . The manual is no help in describing the belts so should I replace it with a 63" belt? I know a belt will stretch/wear so is 1/2" undersize sufficient or should I go to 62". There is no way to adjust the sheaves to get proper tension.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Selecting a belt (Powermatic 16" model 160)

- Thread starter kelLOGg

- Start date

Belts are generic. It should have the size printed on it. There are many belt dimensions, not just diameter and width, but angle. Depending on id Imperial or Metric, the dimension is either working circumference outside. Just to be confusing. If either sheave is less than 3 inches, you really should use a cogged belt.

If you co to Gates, D&D power, Continential or other respectable belt OEMs, you gan get a ful lesson. There is a lot to be learned and many machine makers got it wrong to start with.

Some go with the segmented poly link belts. Be forewarned, all are not of the same quality. Depending on the angle of the V, they are different colors, but come cheap clones don't respect that standard either.

Lastly, stick to the top brand US made belts. The Chinese have never made a round belt. Total crap.

The motor is not on an adjustable base to allow belt tension? I find that almost impossible. Do you have to remove a sheave to install the belts? You can;t "roll" a belt as it destroys the internal structure.

If you co to Gates, D&D power, Continential or other respectable belt OEMs, you gan get a ful lesson. There is a lot to be learned and many machine makers got it wrong to start with.

Some go with the segmented poly link belts. Be forewarned, all are not of the same quality. Depending on the angle of the V, they are different colors, but come cheap clones don't respect that standard either.

Lastly, stick to the top brand US made belts. The Chinese have never made a round belt. Total crap.

The motor is not on an adjustable base to allow belt tension? I find that almost impossible. Do you have to remove a sheave to install the belts? You can;t "roll" a belt as it destroys the internal structure.

There should be a letter and number on the belt. i.e. A-57 the letter is the width of the belt and the number is the length of the belt.

When replacing multiple belts get a matched set different manufactures have different marking on them the marking will be subtle. When the belts are made they put them on a machine the measure stretch.

every tenth of an inch is a different designation.

And if the above dosent help take the belt down to a bearing house and have them match you up with a belt.

When replacing multiple belts get a matched set different manufactures have different marking on them the marking will be subtle. When the belts are made they put them on a machine the measure stretch.

every tenth of an inch is a different designation.

And if the above dosent help take the belt down to a bearing house and have them match you up with a belt.

Years ago (15+ years) I worked at an Advance Auto and we had a device that was basically a larger ruler with a half circle on each end where we could put a v-belt and pull it tight and get a size number for a replacement belt. No clue if they still have this tool, they all seem to rely solely on the computer these days and are quick to say "no" if the computer doesn't tell them the information.

If its no good and youre having trouble measuring its length, cut it and measure it.....

for a start.

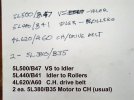

There are 2 bad belts I will replace. One goes around sheaves 'a" and "b" and it was loose enough to slip off. I will replace it with a 1/2 - 63" belt by forcing/twisting/whatever because there is no way to tension it without major disassembly. The bottom sheave "b" is very difficult to access and shows no clear way to remove/slide it. Sheave "a" is 5/8" wide and can slide 7/16" so there is no way to remove it and slip a belt around it and reinstall. (Planer weighs 1200 lbs)

Belt "c" has a large crack and it was easy to remove by sliding the sheaves off. It is a 5/8 - 45". I will get cog belts at the Surplus Center where I have had good luck for decades. Thanks for the chart and advice.

Belt "c" has a large crack and it was easy to remove by sliding the sheaves off. It is a 5/8 - 45". I will get cog belts at the Surplus Center where I have had good luck for decades. Thanks for the chart and advice.

A belt that was forced, rolled etc. will be damaged. That is all there is too it. Sorry. If you can't adjust tension, then the link belt thingies won't work. It is hard to imagine a V-belt that can't be tensioned. Specific tension defines the ability to transmit power.

The model 160 shown in the video was different from my model 160 but was close enough to give me confidence to proceed. I was able to remove the assembly containing belt "b" in reply #7 and, sure enough, one of the mounting holes was slotted to allow pivoting for tensioning. However, pivoting was insufficient because the axle housing on the pivoting assembly would hit part of the cast iron base. (Manufacturing defect 57 years ago, IMO) I had to grind the opening a quarter inch wider to allow more pivoting and installation of the new belt. The working conditions were awful due to weight (~25 lbs) of the assembly and awkward accessibility. Sorry, no pics, I was far too dirty to pick up my iPhone. One more belt to put on -- when it arrives - and hopefully all will be done.

What was shown in that video is the little 12" model 100. As observed, it is quite similar to the 160/180 models except for scale. I'm sorry I didn't see this thread earlier. I have a set of belts for the 160/180 planer in stock. It was common to find bad belts on some of those planers. Yes, replacing those belts could take an hour or two and yes, it was a major pain. Loosening the adjustment bolts and jerking the heck out of the belt would usually give enough slack to get the belt off.

Consider fully wrapped belts, particularly on the VS drive. They seem to last better.

an OWWM.org thread on roller removal: https://www.owwm.org/viewtopic.php?f=1&t=164622

Below some shots of the process

Consider fully wrapped belts, particularly on the VS drive. They seem to last better.

an OWWM.org thread on roller removal: https://www.owwm.org/viewtopic.php?f=1&t=164622

Below some shots of the process

The 160 and 180 are virtually the same except for width of defining components. The 180 came with adjustable bed rollers standard while many of the 160s had it as an option. Its my favorite planer partly because I've worked with a lot of them and partly because I have one. Once set up, it will do a wonderful job of quickly reducing thickness. Usually I can take 4/4 rough stock that has been face jointed down to 3/4" net in three passes. Doing it in one pass has a tendency to leave a rough surface. I try not to take off more than 3/16" per pass.There' a lot of useful info up there, Bob. That will make a good reference.

LATEST FOR SALE LISTINGS

-

-

Graco 395 FinishPro air assisted airless sprayer for sale

- Started by RobH

- Replies: 1

-

-

-