You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

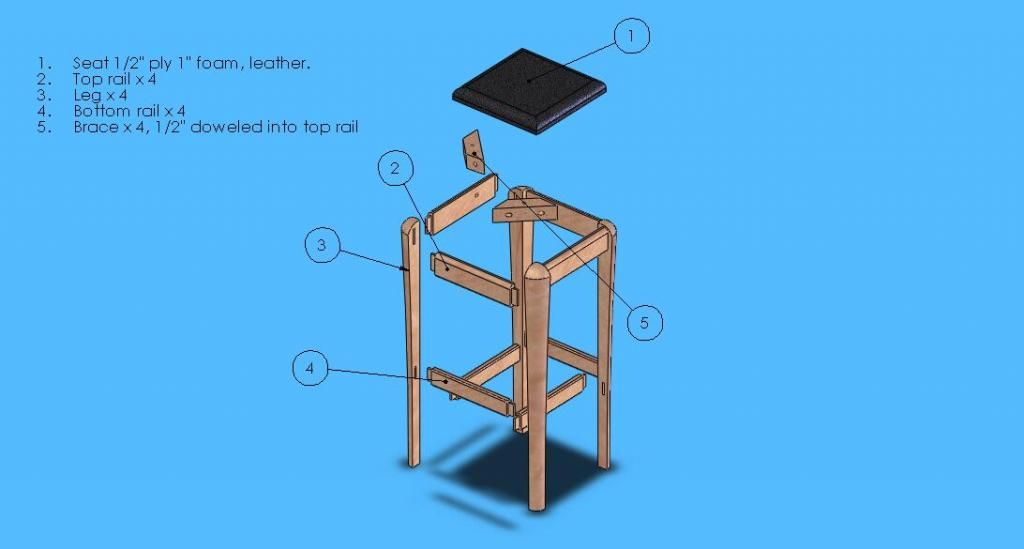

Furniture grade bar stools

- Thread starter Willemjm

- Start date

- Status

- Not open for further replies.

Very nice, Willem. Were these for you or a client?

Bill

Bill

Another fine job :thumbs_up

Great looking stools! :eusa_clap:eusa_clap:eusa_clap:eusa_clap:eusa_clap:eusa_clap

Question about making the legs- Did you make each leg separately or did you glue up 4 pieces with paper between each, turn the assembly on a lathe and then break them apart?

Question about making the legs- Did you make each leg separately or did you glue up 4 pieces with paper between each, turn the assembly on a lathe and then break them apart?

Thx everyone for the complements.

Answers to questions:

Not a commission, built for myself.

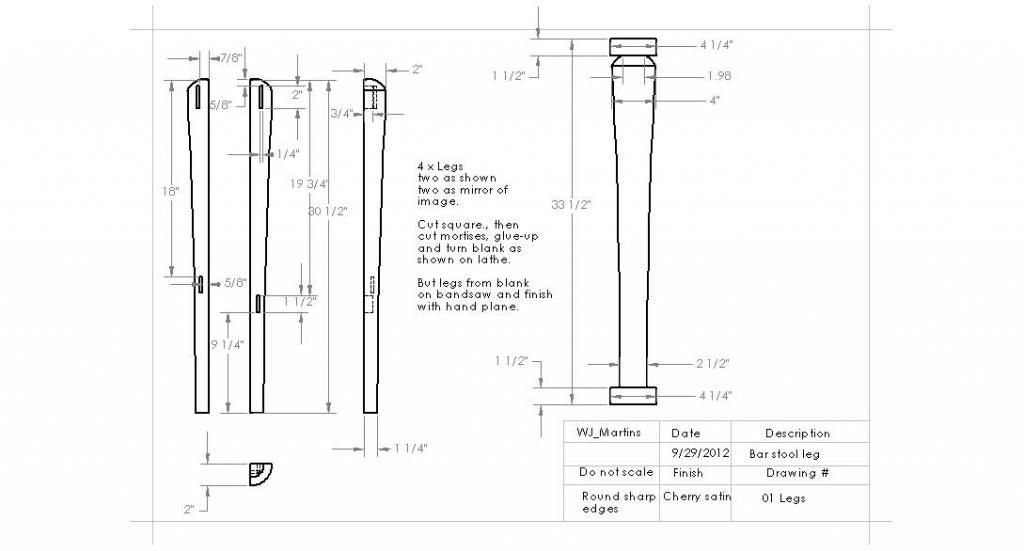

Legs were glued up and turned on the lathe, then cut apart on the bandsaw. The glued up blank is shown in the last drawing. I did not use paper, have not tried that before.

Answers to questions:

Not a commission, built for myself.

Legs were glued up and turned on the lathe, then cut apart on the bandsaw. The glued up blank is shown in the last drawing. I did not use paper, have not tried that before.

Well done. Looks beautiful. The cherry is beautiful and looks finished very nicely.

Really nice stools Willem. They look right at home with all the other wonderful hand made furniture in your home.

Thx everyone for the complements.

Answers to questions:

Not a commission, built for myself.

Legs were glued up and turned on the lathe, then cut apart on the bandsaw. The glued up blank is shown in the last drawing. I did not use paper, have not tried that before.

Sorry, I missed that.

I have done it with other parts and it works pretty well. When you split it apart the fibers of the paper just part. You still need to clean up the faces with a plane or a quick pass over the jointer.

Willem,

did you perform the mortising prior to the glue up? I would think it would be hard to jig the legs after the lathe work. BTW, very nice work.

mike

Here ya go:

Cut all the mortises

To line things up perfectly, put loose tenons in the mortises and put glue in three spots on the sticks, clamp together to glue up.

Turn on the lathe and leave squares on each end.

Screw a 3/4" plywood strip on the squares, cut apart on the glue lines with the bandsaw (2 cuts), send across the jointer, sand up to 220 and then saw off the square ends on the miter saw.

Woodworking, a thinking man's sport! :eusa_clap

I wonder how that technique would work with cabriole legs. It would still require some serious leg shaping on the insides and where the curve meets the flat sides and the feet would need a bit of work too, but the at least the outside faces of the leg and ankle would be identical. It might be worth an experiment unless someone has already tried and written about it somewhere.

I wonder how that technique would work with cabriole legs. It would still require some serious leg shaping on the insides and where the curve meets the flat sides and the feet would need a bit of work too, but the at least the outside faces of the leg and ankle would be identical. It might be worth an experiment unless someone has already tried and written about it somewhere.

Beautiful! Thanks, great lesson.

- Status

- Not open for further replies.

LATEST FOR SALE LISTINGS

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1

-

-