Hey Everyone,

I recently joined NCWW and here goes my first post. Actually it's my first on here or on any forum. Haha hope I did it right!

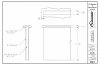

I have a friend who had a local sawmill cut him a live edge handrail out of sweet gum. It is 3" thick and 20' +/- long and roughly 10" wide. We plan to cut a recess the bottom to fit over a knee wall above his stairs. The recess will be 4.75" wide, 1.5" deep and will run the entire length of the handrail.

I have been told that you can use a good epoxy to finish green wood and by sealing all sides you wouldn't have to let the wood dry first. I keep WEST System 105 epoxy resin in the shop and would probably use it for the finish. Usually I'm all about trying something new even when i don't think it will work and I've learned a lot from many mistakes! But I hate to waste all that epoxy if it doesn't work. I wouldn't be able to attach it with screws or the penetrations in the finish would allow the moisture to get out. My plan was to use a good flexible adhesive that would stay soft and allow everything to move a little.

My first idea was to let it dry; but patience doesn't seem to be my friends strong suite. So now I'm hoping someone has tried this before and if not guess I'll be the guinea pig!

Open to any thoughts or ideas!

Thanks, Chris

I recently joined NCWW and here goes my first post. Actually it's my first on here or on any forum. Haha hope I did it right!

I have a friend who had a local sawmill cut him a live edge handrail out of sweet gum. It is 3" thick and 20' +/- long and roughly 10" wide. We plan to cut a recess the bottom to fit over a knee wall above his stairs. The recess will be 4.75" wide, 1.5" deep and will run the entire length of the handrail.

I have been told that you can use a good epoxy to finish green wood and by sealing all sides you wouldn't have to let the wood dry first. I keep WEST System 105 epoxy resin in the shop and would probably use it for the finish. Usually I'm all about trying something new even when i don't think it will work and I've learned a lot from many mistakes! But I hate to waste all that epoxy if it doesn't work. I wouldn't be able to attach it with screws or the penetrations in the finish would allow the moisture to get out. My plan was to use a good flexible adhesive that would stay soft and allow everything to move a little.

My first idea was to let it dry; but patience doesn't seem to be my friends strong suite. So now I'm hoping someone has tried this before and if not guess I'll be the guinea pig!

Open to any thoughts or ideas!

Thanks, Chris