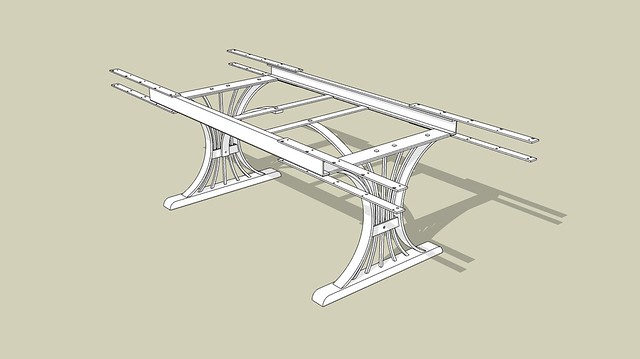

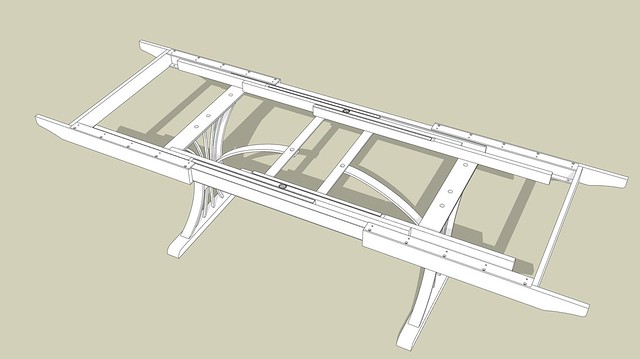

I thought I'd share some images of a dining table I designed for clients in New York City. They wanted an extension table large enough to seat 10, or even 12, for their frequent large Friday night meals but they wanted it to suit their smaller family the rest of the week. They asked for a wood top and steel base. This is what I presented.

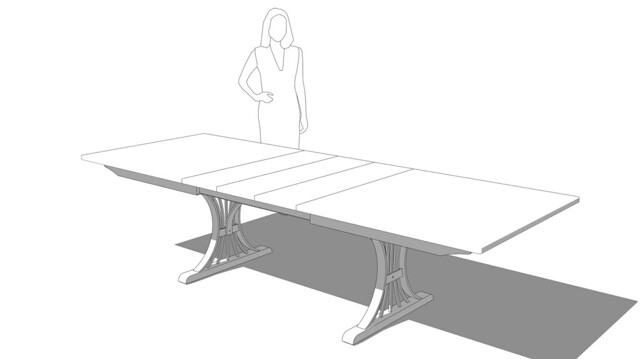

With the leaves in.

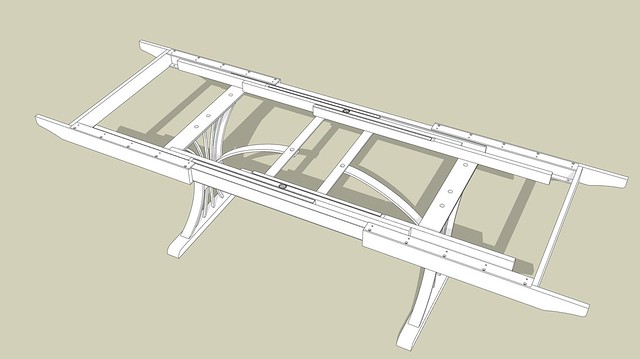

I spec'd equalizer slides from Osborne Wood Products which worked quite nicely.

And here are pictures of the finished table in place. The table was built in Hendersonville, NC.

Unfortunately those are the best photos I have.

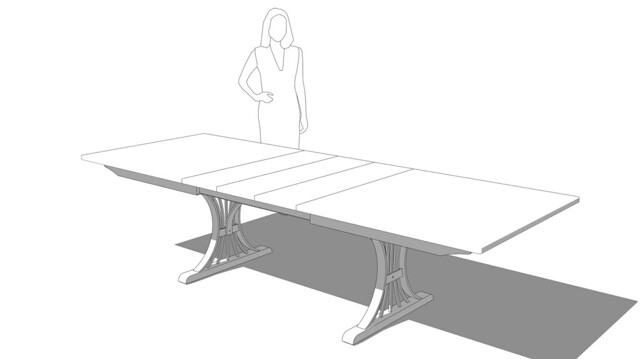

With the leaves in.

I spec'd equalizer slides from Osborne Wood Products which worked quite nicely.

And here are pictures of the finished table in place. The table was built in Hendersonville, NC.

Unfortunately those are the best photos I have.