I need some advice.

SO, I have a single car garage most of my wood working tools and stuff is in. The wife is getting a washroom/mudroom build into the back section so that it taking away about 10 feet BUT all of her pantry stuff and freezer will be going in that room so in the end I may be gaining space. Maybe its a wash, dunno.

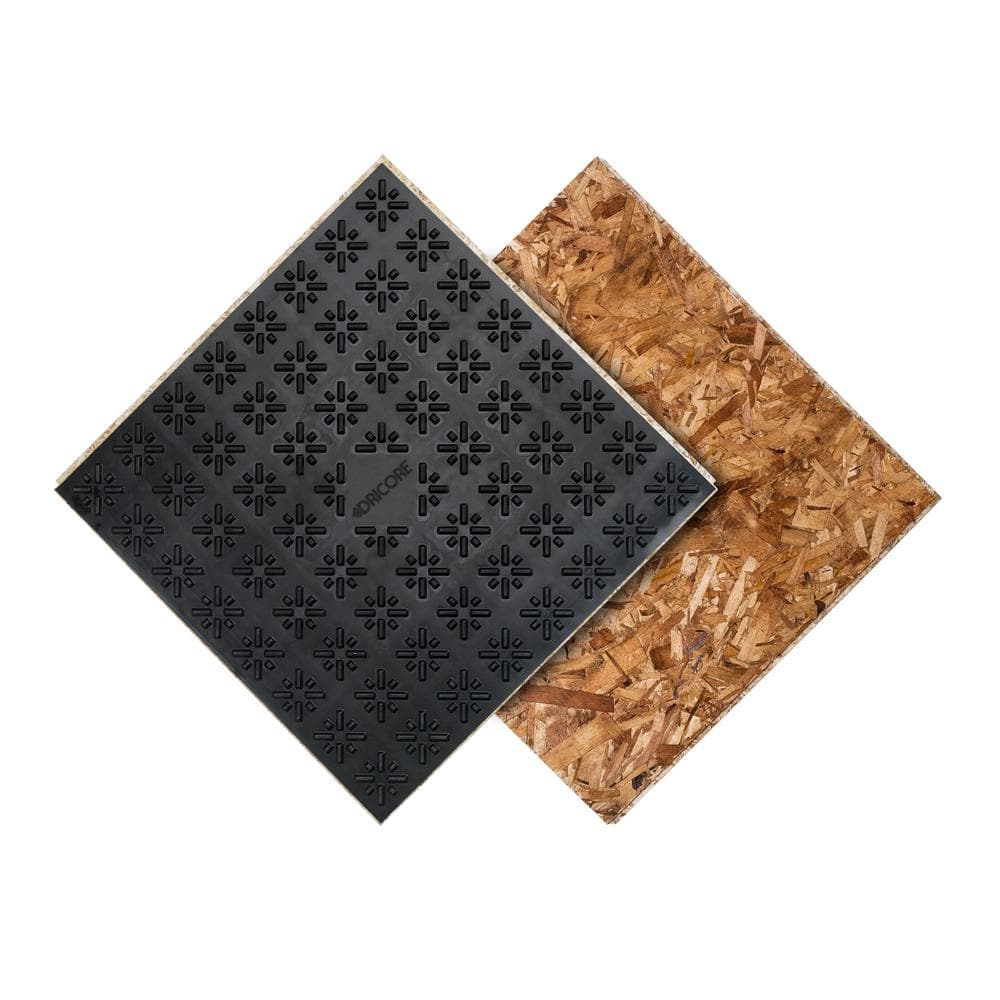

Anyway, I want to do something about the cement floor. The hope is the level it and get a cover of some kind be it epoxy, mats or some other product. Anyone have experience with this and can provide some guidance, advice, or contacts concerning this sort of work?

UPDATE: The house was built in the mid 80s, I think around 1986. So it is a narrow, single car 80s garage space. No vehicle are in it nor will there be and even if I wanted there to be modern cars are too big. The cement floor is uneven and has small spot broken out form previous owners. Vehicle fluids may be stored in the garage but vehicles will not be in there to be worked on due to space constraints.

My main goal is a floor that will allow me to work out there for, potentially, extended periods of time that will not cause me to hurt from standing on plain cement. This bearing in mind I am a medically retired veteran with a variety of military injuries combined with a more recently broken pelvis. That impact over time does matter on joints and I want to keep doing woodworking for a long time as I am still pretty young.

I also understand that a certain sloping grade is required for drainage. This work is something I would likely pay to be done rather than do by myself. That is why I was asking for advice or referrals. I am also down in Fayetteville near Fort Bragg if that makes a difference on referrals.

SO, I have a single car garage most of my wood working tools and stuff is in. The wife is getting a washroom/mudroom build into the back section so that it taking away about 10 feet BUT all of her pantry stuff and freezer will be going in that room so in the end I may be gaining space. Maybe its a wash, dunno.

Anyway, I want to do something about the cement floor. The hope is the level it and get a cover of some kind be it epoxy, mats or some other product. Anyone have experience with this and can provide some guidance, advice, or contacts concerning this sort of work?

UPDATE: The house was built in the mid 80s, I think around 1986. So it is a narrow, single car 80s garage space. No vehicle are in it nor will there be and even if I wanted there to be modern cars are too big. The cement floor is uneven and has small spot broken out form previous owners. Vehicle fluids may be stored in the garage but vehicles will not be in there to be worked on due to space constraints.

My main goal is a floor that will allow me to work out there for, potentially, extended periods of time that will not cause me to hurt from standing on plain cement. This bearing in mind I am a medically retired veteran with a variety of military injuries combined with a more recently broken pelvis. That impact over time does matter on joints and I want to keep doing woodworking for a long time as I am still pretty young.

I also understand that a certain sloping grade is required for drainage. This work is something I would likely pay to be done rather than do by myself. That is why I was asking for advice or referrals. I am also down in Fayetteville near Fort Bragg if that makes a difference on referrals.

Last edited: