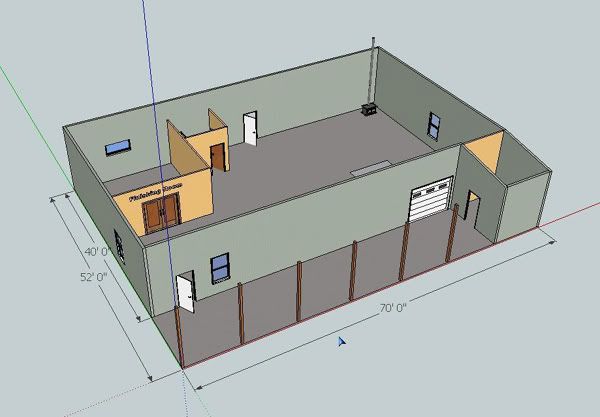

I have my shop walls up and floor is poured (40x70 pole building with 14ft ceiling). The next step to to put up interior walls for finishing room and bathroom.

The bathroom walls should not be too tough - just 2x4 walls, 16" oc, 8ft ceiling. I plan to put the water heater on top of the bathroom, so I need a floor on top.

The finishing room will be more of a challenge. Size is 20x20 ft, so I have a big span to cover. I plan to have 9ft ceiling, and use overhead as main storage area. Will need to built like a second floor? Not sure if I can use 2x12s to span the distance and carry the load. 2x4 walls, or 2x6 needed?

Looking for advise, and maybe links to other building help/forum sites for information on best approach to building these rooms.

The bathroom walls should not be too tough - just 2x4 walls, 16" oc, 8ft ceiling. I plan to put the water heater on top of the bathroom, so I need a floor on top.

The finishing room will be more of a challenge. Size is 20x20 ft, so I have a big span to cover. I plan to have 9ft ceiling, and use overhead as main storage area. Will need to built like a second floor? Not sure if I can use 2x12s to span the distance and carry the load. 2x4 walls, or 2x6 needed?

Looking for advise, and maybe links to other building help/forum sites for information on best approach to building these rooms.